Barista Troubleshooting Guide

Serving coffee doesn’t always go to plan. At Coffee Cup Equipment we know that not being able to serve good coffee is an emergency! Take a look at our barista troubleshooting guide, it will help you run your operation more smoothly, and also explains where we can step in and help.

1) Grind Adjustments – Yesterday your espresso was extracting in a well-balanced 30-35. This morning the coffee is dripping through very slowly leading to over-extraction and a long wait for each customer. We could blame this on our colleagues, the machine, or the Grinder Fairy. Of course we need to figure out why this has happened but first we need to fix the problem so we can get back to serving delicious coffee. In this example the coffee needs to be ground coarser and a quick grind adjustment is all that is needed. We can help you fix this in 5 minutes over the telephone or we can send an engineer to help you on-site.

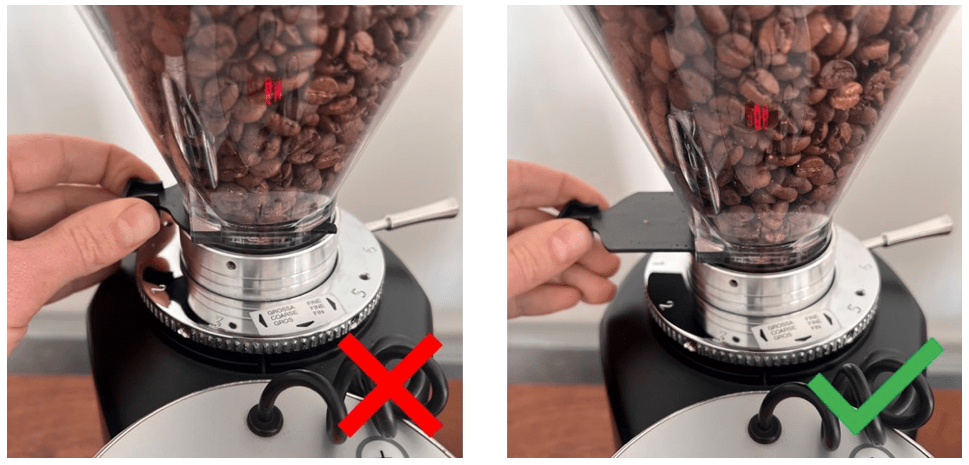

2) The hatch at the bottom of the hopper is closed – In our experience, the customer calls saying the grinder is not working. Invariably, this is because the hatch at the bottom of the hopper is closed. This is a hatch that slides in and out to open or close the exit at the bottom of the hopper. When grinding, it needs to be open so the beans fall down into the grinder burrs. You need to close it when removing the hopper so the beans don’t fall everywhere. It’s a long journey for our engineers when they arrive to find this is the only problem, but we’ll usually identify the matter over the telephone.

3) We have lost the basket or spring that goes in the handle – These often end up in the bin – so check there first! Call us if you can’t find it and we’ll send a new one in the post as it’s a small item. If you have to replace it yourself it will take time to research what to buy, and to be delivered.

4) The machine is not working – Usually, it’s just not been switched on, so not much explanation needed here! Typically, we identify this quickly over the telephone.

5) The machine is switched on but there is a problem with the electrical supply – Maybe you’ve had a new piece of equipment installed on the same ring main and it is therefore overloaded. Then turning the machine on in the morning may have caused the fuse to trip. We send an engineer to check the coffee machine to eliminate it as the cause and advise the customer of the electrical problem they have. Of course, if the problem is the espresso machine, we fix it then and there!

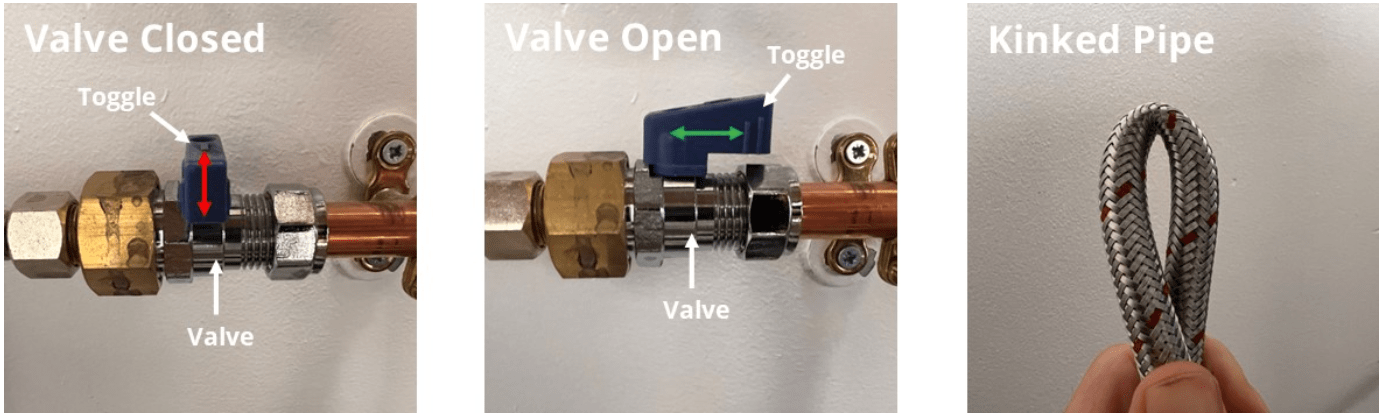

6) The water supply has been compromised – If we receive a call from a customer who says there is no group (coffee) water and or the lights on the machine are flashing, this means that there is insufficient mains water supply to the coffee machine. This happens a lot when there have been workmen doing another job and have forgotten to turn the water supply back on to the espresso machine, but it can also be accidentally turned off. The water supply toggle is most likely, under the counter on the water supply pipe before it enters the water filter. If the toggle is in-line with the valve it is open, but if the toggle is perpendicular to the valve it is closed and needs to be opened. Turn the toggle and the water supply will return to the coffee machine. The water supply hose can also can be kinked due to crates or other heavy supplies being squeezed into the same cupboard. Another thing we may ask you to check for over the telephone.

There are other reasons why the water supply can be compromised. So, if these avenues are explored and found not to be the cause we will send an engineer to help.

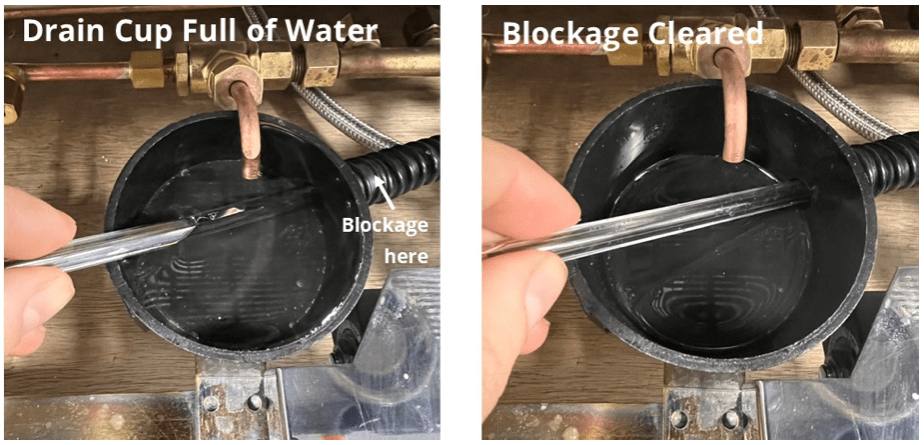

7) The waste is blocked – The waste pipe that exits the drip tray and goes into the building drain can easily get blocked, especially if the barista lets the wet pucks of coffee go down the tray instead of in the bin. Sometimes the blockage can be cleared by the barista. If you remove the drip tray you will see the drain cup, which will be full or overflowing with water. Take a pen and stick it down the hole to the waste pipe, give it a wiggle and the drain cup will empty down the waste pipe. It’s a good idea to then pour a litre or two of water down the waste to wash away any more debris that may be in the pipe and cause a blockage later.

If the blockage is further down the pipe we will send an engineer to unblock it for you. This is a dirty job, but it needs to be done and only takes a few minutes. Afterwards, if possible we will improve the positioning and angle of the waste to avoid it happening again.

8) There is coffee water continually pouring from the group – This can be because the semi-automatic switch is on. You can control the flow of water from the group by the programmable doser pads (which is what most people use as it stops the extraction automatically), but there is a second option which is the semi-automatic switch. This switch is pressed once to start the extraction and has to be pressed again to stop it, so when it is switched on by accident the water will continually flow from the group. It just needs switching off.

9) The machine is making a loud noise – All espresso machines vibrate to some extent when the motor is running. There may be something leaning against the machine or some other piece of equipment may have been moved so it is in contact with it, causing more vibrations and a loud noise. Otherwise it can be the drip tray vibrating, which repositioning slightly can help or the cups on the top of the machine. Sometimes the vibration is internal and in this case we send an engineer to fix the problem.

10) The coffee is cold – You may have customers complain about this, or you may notice It yourself. Firstly we check the machine is functioning as it should do over the phone. This is done using the pressure gauge on the machine, to check the temperature of the water in the boiler. Once we have eliminated the equipment as the problem, we usually find it to be caused by one of two reasons: 1) The customer has ordered a milky drink, but milk can’t be steamed to over 65 degrees or it will start to cook and smell eggy. But they don’t accept this and complain to the barista. In this circumstance the customer can usually be satisfied by offering them an americano which is mainly hot water, but the problem is often blamed on the espresso machine. 2) Cold cups! If you add coffee to a porcelain cup that is cold it will very quickly remove the heat from the coffee. Similarly a cold portafilter (handle) will remove the heat from the coffee. Always use warm cups and keep your portafilters in the group when you are not using them to keep them nice and toasty! This can be difficult to resolve over the phone, but the pressure gauge doesn’t lie, so we often send an engineer to demonstrate on-site.

11) The milk isn’t steaming – The fat content in the milk is paramount to creating micro foam. If the farmers have changed their feeding process or feed itself, this can change the milk they sell you without your knowledge. Correct storage of the milk is also important and if not kept cold it can cause a similar problem. The first thing you will know of this, is that the milk is just not steaming/aerating as it should. The answer is to try a different brand of milk from a different retailer. Otherwise, the milk may need shaking every time you pour it into the milk jug. We will always check the functionality of the machine as well, but if the boiler pressure is as it should be, steam is steam, and it is more likely to be the milk.

12) The Coffee Tastes Bitter – There are 4 things that can cause this. 1) If the coffee is roasted dark it will carbonise and therefore taste bitter (like burnt toast). You can tell by the darkness of the bean, but if you are unsure, chew up a bean in your mouth, this will tell you if your coffee is slightly burnt or not. 2). The coffee will taste bitter if it is over-extracted, this problem is resolved by adjusting the grinder (see no 1, Grind adjustments or our ”how to adjust your Mazzer On-Demand Grinder video”) and maybe tweaking the recipe. 3) It can be caused if the equipment isn’t cleaned thoroughly. This is not aesthetic cleaning but cleaning the inside of the group using a process called backflushing. It involves putting a small amount of cleaning powder into a handle with the blanking plate (like the filter basket but with no holes) fitted instead of the basket so that when the water hits it, it goes back into the machine with the soap instead of into the cup with the coffee. Also cleaning the handles is important. If you do not do these things regularly a bitter layer of old coffee will build up and taint the flavour of the coffee.

13) One of the steam arms isn’t working – Both of the steam wands are supplied by the same boiler, so if there is no steam from both of the steam wands it probable that there is no steam in the boiler. If it’s just one of the steam wands we know there is steam in the boiler. It could be a mechanical problem with the tap but if the knob turns you will always get some steam. Therefore if there’s no steam at all it is because the small holes in the end of the steam tip are blocked with dried milk! The baristas have not purged the steam wand after using it to remove the milk from the little holes. It has dried and is now stopping the steam exiting the end of the steam wand. We can help the customer with this over the telephone by asking them to unscrew the steam tip, clean it and put it back on. Or they can use a paperclip to clear the holes, but this way they are pushing dry milk up into the steam wand.

14) There is green or black slime in the water level sight glass – This is an indication that the water supply to the machine is being softened twice! We always fit a water filter system to the mains water supply before it enters the espresso machine. However, there may be another water filter that filters all of the water before it enters your building. If the water is over softened the acidity is increased and the mineral content is reduced. This de-ionises the copper washer and combines with sulphate to create the green colour. If you see green or black stuff in the sight glass of your espresso machine please let us know as soon as possible. We will send someone to test the water so we can find a solution. Once this is fixed the coffee will taste better too!

15) Water trickles down the side of the portafilter (handle) when I make a coffee – When you insert the portafilter into the group and pull it round, the rim of the metal basket makes a water tight seal with the rubber gasket in the group. The water will leak from here if there is not a water tight seal. This could be because the rubber gasket has become hard over time and needs to be replaced. The other reason is that the rubber gasket has a build-up of coffee stuck to it and simply needs a clean. Use the group brush to clean the rubber gasket in the group at the end of each day and keep the coffee machine in top condition. It is also a good idea to make sure there are no coffee grounds on the rim of the metal basket when you insert it into the group. Simply wipe them away with your finger. If you try this and it doesn’t help, all you need to do is give us a call and we will have an engineer with you in a jiffy, to replace the gaskets and check the rest of the machine over.

If you try this and it doesn’t help, all you need to do is give us a call and we will have an engineer with you in a jiffy, to replace the gaskets and check the rest of the machine over.

16) The group water looks dirty or has bits of coffee in it – This is caused by not backflushing the group. This is an essential part of cleaning maintenance for your espresso machine. Take the blanking plate (like the filter basket but with no holes). This is the shallow basket that fits into the portafilter but has no holes – go ahead & pop it into the portafilter in the place of one of your filter baskets. Take the cleaning powder and add ½ a teaspoon to the solid basket. Don’t add too much or you will block the group with soap! Inset the portafilter into the group. Run the group for 10 seconds and then stop, do this 3 times. When the water hits the solid plate it rebounds back up into the group and cleans it – known as backflushing! Then remove the portafilter, wash the dirty soap out of the solid basket and do the same thing with no soap. This is to wash the soap away. Once done it can’t hurt to run the group for 30 seconds just to make sure there is no soap left in the group. If you do this and the water is still dirty, you need to do it again until it is clean. Check out our backflushing video for further information.